Details

Standard Features

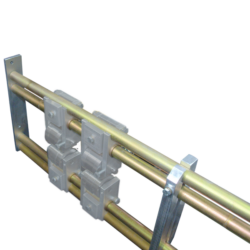

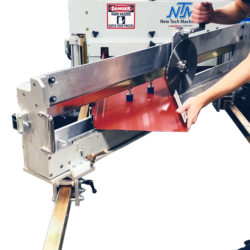

- Polyurethane Drive Rollers

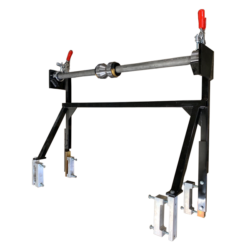

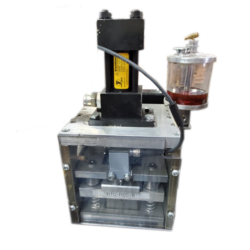

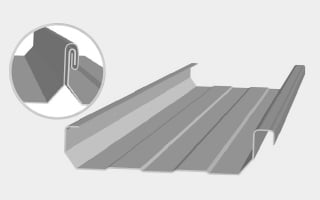

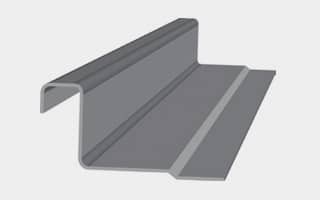

- Roller System with Shear Dies

- Hydraulic Drive & Shear

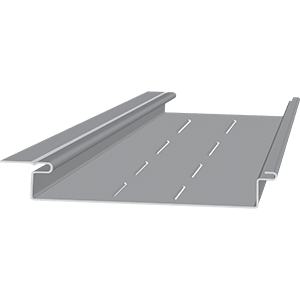

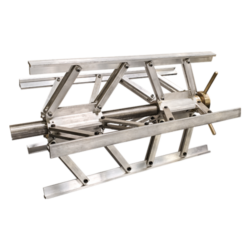

- Powder-Coated Frame

- Aluminum Covers

- Welded Tubular Steel Frame

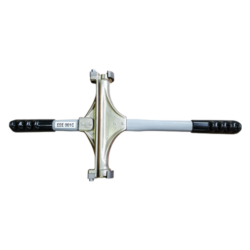

- Push Button RUN/JOG Controls at Entry & Exit Ends

- Power Interruption Safety Circuit

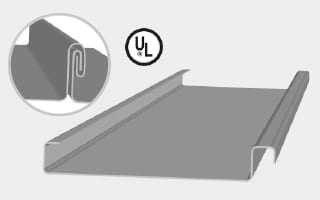

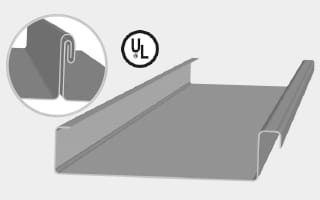

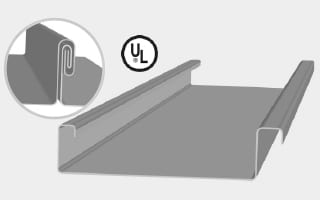

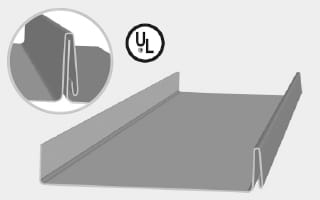

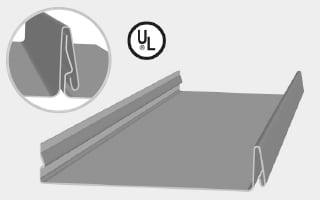

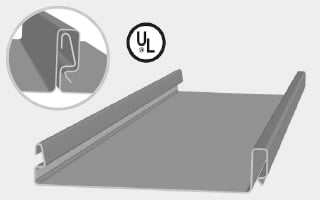

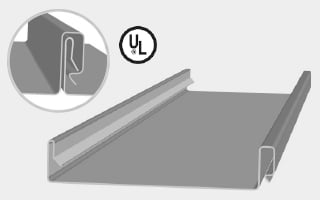

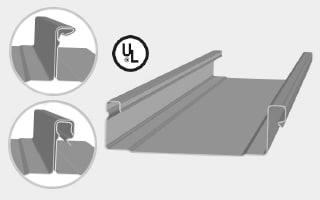

- UL Rated Panels (Must Be Certified by UL for Recognition)

- Industry’s Best Warranty

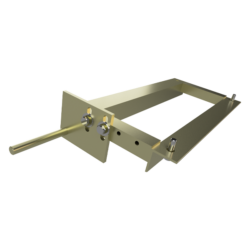

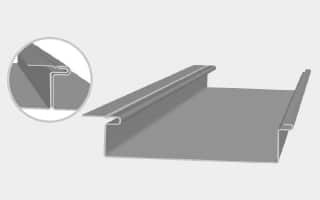

- Choice of: Quick-ChangeTM Profile Roller System

- Choice of: Quick-ChangeTM Power-Pack (Gas or Electric)

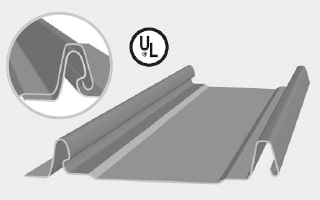

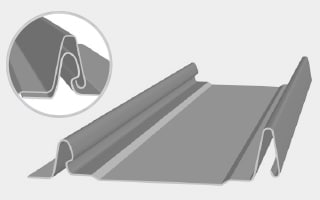

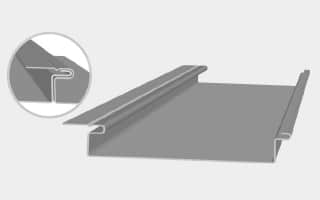

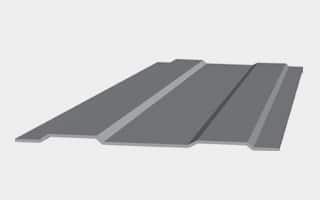

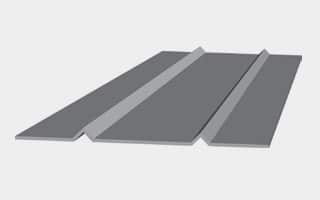

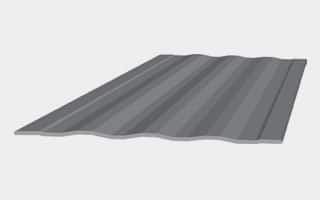

- Choice of: One Pair of Bead, Pencil, Striation or V-Rib Rollers

Warranties & Patents

Warranty:

New Tech Machinery provides a limited three-year part and NTM in-house labor warranty. Read more about our warranty here.

Patents:

- U.S. PATENT NO. 6,772,616

Profile Disclaimer:

- New Tech Machinery provides no warranty (finish, substrate or weather tight) in relation to the metal roofing systems the machines form. Should a warranty be required, users should consult with metal roof manufacturer or coil supplier prior to contracting on work. It is the sole responsibility of the installer and/or metal panel manufacturer to ensure that the roof system meets all engineering and local building codes.