What Is a Portable Rollforming Machine? Equipment Types & Uses

If you want to get into the metal roofing or gutter industry, you’re likely looking to learn more about the equipment and machinery needed to compete within the industry. Alternatively, maybe you’ve been installing for a while and want to purchase your own machine or expand your business to produce panels and sell to others.

The best way to accomplish this is to purchase or lease portable rollforming equipment, whether it be metal roofing machinery, gutter machinery, or both.

However, how much do you know about portable rollforming equipment? Do you know the different uses, advantages, and disadvantages this type of rollformer offers?

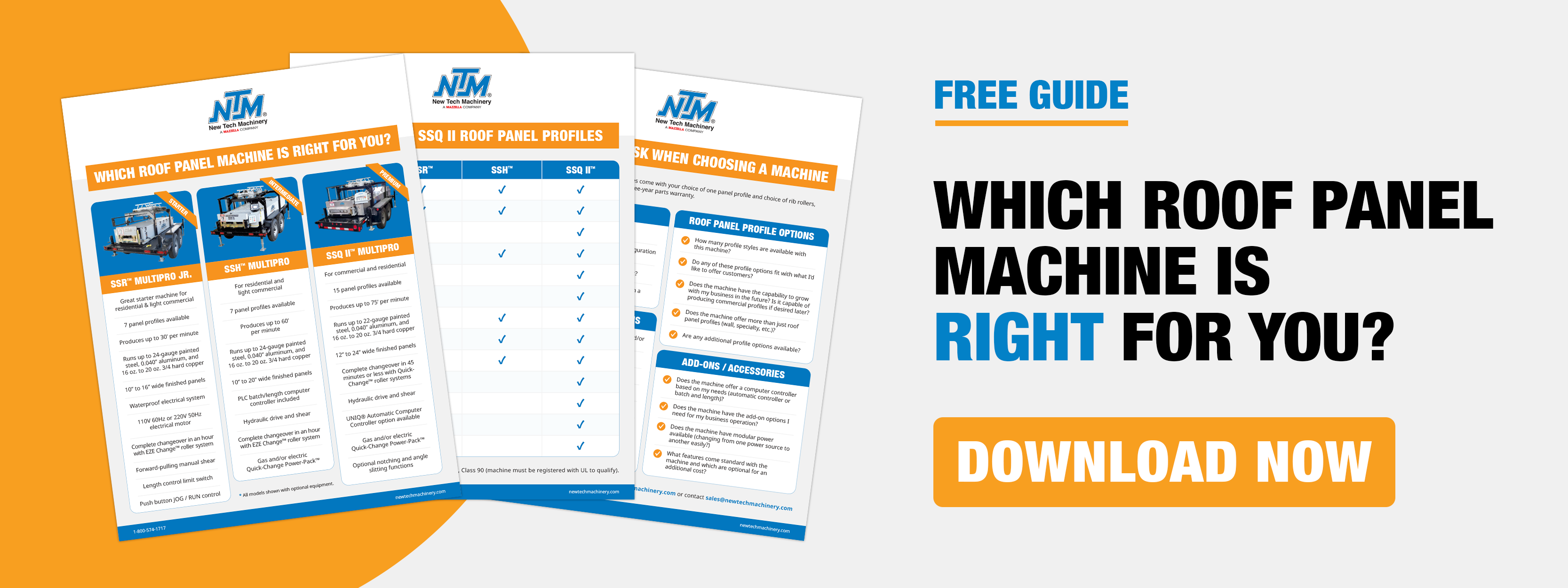

Since 1991, New Tech Machinery has helped contractors worldwide gain more control of their projects and profits by manufacturing the world’s finest portable rollforming machines, so we know the importance of being an educated consumer before you go to buy this equipment.

In this article, expect to learn:

- What portable rollforming is and how it differs from in-plant rollforming

- The different machines and available functions

- Uses and specific products made with rollformers

- Advantages and disadvantages of portable rollforming

What Is Portable Rollforming?

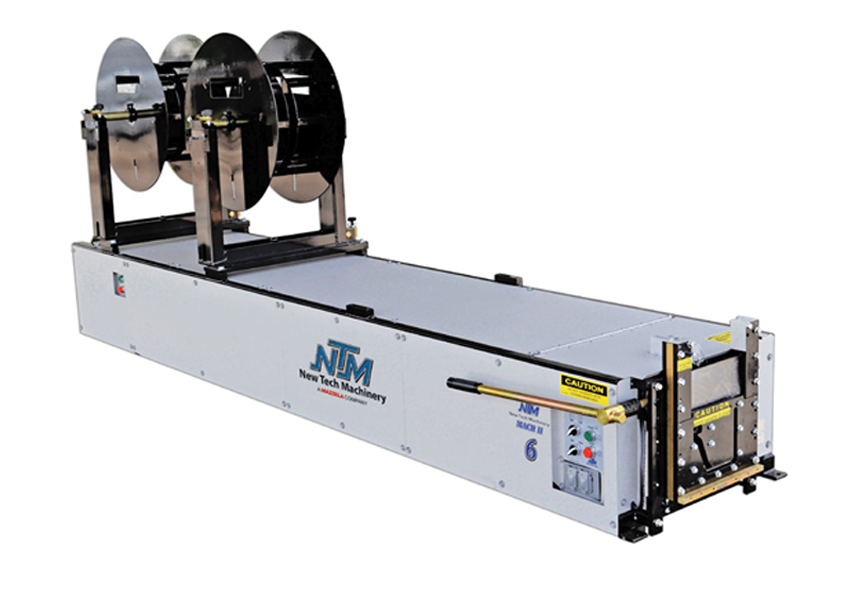

Metal rollforming is defined as the process of feeding metal, whether it’s finished, coiled, flat, or otherwise, through a series of rollers where each roller station further manipulates the piece of metal into the desired shape. Portable rollforming is this same metal rollforming idea just on a condensed level and takes everything a typical rollformer does and packs it into a smaller size so it can be transported easily.

A portable metal roofing or gutter rollforming machine operates very similar, if not the same, to an in-plant machine:

- The metal coil material gets fed into the machine from the decoiler.

- The drive rollers pull the metal through the inside of the machine.

- The metal goes through the forming rollers at each forming station, where the panel or gutter gradually forms into the desired end product.

- Depending on the profile, most portable metal roofing and gutter machines have around 11 to 14 rolling stations on each side.

- The panel or gutter is cut using a shear or guillotine at the specified length, which is either measured by hand or controlled by a computer (either manual or automated depending on the machine)

What Makes a Rollformer “Portable”?

You might be thinking that the smaller size of a portable rollformer is the only true difference between in-plant and portable machines. However, other distinguishing characteristics make a rollformer portable, such as:

- The option to have the rollformer mounted on a trailer – Some contractors don’t want to haul their rollformers around in their work vehicles or trucks. Instead, they can opt to tow their machine anywhere using a trailer, which can attach to a variety of vehicles.

- Ability to take it out into the field – Having a portable rollformer allows contractors to take their machines directly to the job site. Not only is this convenient, but it also helps the contractor continuously install panels or gutters without waiting and saves on shipping or other middleman costs.

- All-in-one unit – To complete the entire portable rollforming unit, many machines often come with an attached or stand-alone decoiler for the metal and run-out tables for the finished panels.

- Portable power options – Most in-plant rollformers are electric only, but portable metal roofing rollforming equipment comes with the choice of gas or electric as the power source. Gas tends to be more common and convenient for portable roof panel rollforming, but others do buy generators to use for electric-powered machines. Residential gutter machines are typically electric-powered with 110V power in North America; 220V, 12V, and CE wiring are also available.

Types of Portable Rollforming Machinery & Products

Metal Roofing Portable Rollforming Machines & Equipment

With metal roofing’s growing popularity due to its longevity, strength, options, colors, and more, metal roofing portable rollformers are in high demand from both contractors and manufacturers. In addition to the panels produced for roofing structures, some machines can make various metal wall and specialty panels. Options include various:

- Profiles – Snap-lock, mechanical seam, exposed fastener lap seam, tee panel, 5V crimp

- Flat or rib rollers (panels can be rollformed flat or have decorative/stiffening ribs added) – Clip relief, bead ribs, pencil ribs, v-ribs, striations, corrugated

- Metal materials – Steel (Galvalume®, galvanized, stainless, COR-TEN®), aluminum, copper, zinc

- Sizes – Lengths, widths, gauges of the panels produced

- Additional functions and machines – Notching function, slitting machines, hemming machines, eave-shearing machines, tapered machines

Gutter Portable Rollforming Machines & Equipment

As someone who works in the metal roofing or gutter system industry, whether you’re installing the panels yourself or own your own business, you want to know who else uses portable rollforming equipment, right?

- Residential metal roofing/wall system contractors

- Commercial metal roofing/wall system contractors

- Residential and commercial gutter contractors

- “Cut & drop” (sometimes called “chop & drop”) panel suppliers or manufacturers

- Factory/in-plant panel and gutter manufacturers

- Other construction industry professionals

- Architects or designers – Many often want to hire contractors who own portable rollforming equipment on their projects

Advantages and Disadvantages of Portable Rollformers

When weighing your options and determining if a portable rollformer is best for you or your company, it honestly just depends on your needs. Much like any product or service, there are both advantages and disadvantages to using portable rollforming equipment.

Advantages of Portable Rollforming

Portable – It’s probably pretty obvious, as portable is right in the product title, but one of the most significant benefits is that these machines can be taken to any job site with or without a trailer attachment.

No wait times – Owning or leasing a portable rollformer cuts out the time spent waiting for panel deliveries. Not only does this cut out waiting time, but it also allows you to work on a more continuous schedule rather than adhering to the manufacturer or supplier’s timeline.

No shipping needed – Having your own portable rollforming machine cuts out the cost of shipping as well.

Profile/roller set (tooling) changeover – Many portable rollformers, such as the NTM SSQ II™ MultiPro Roof Panel Machine, offer the option to purchase more than one profile/roller set. These options allow you to provide more versatility to your customers and bid a job knowing that you can easily add profiles. Also, changeovers (or tooling changes) take significantly less time, around 45 minutes or less, than in-plant rollformers, which can take hours in larger machines.

Machine accessibility & versatility – With the proper lifting mechanism, portable rollformers can be lifted to the height of a structure’s roof if desired. Also adding to versatility is the fact that portable rollformers can fit into many different vehicles instead of on a trailer, especially if you’re looking for a more cost-effective solution.

Continuous work – Portable rollformers, while not as speedy as in-plant rollformers, produce enough panels on-site so the installers can continuously put panels up without stopping.

Less waste produced – Let’s say that you don’t own or lease a rollformer, so you order panels from a regional manufacturer. If the manufacturer makes a mistake, delivers the wrong panels/lengths, or damage occurs during shipping, it’s a complete waste of both time and materials and can even lead fines/liquidation damages if too much time is lost. With portable rollforming, you can ensure you make the right panels the first time around with little to no wasted metal.

Business diversification – If your machine is sitting idle, you have the option to run a “cut and drop” operation where you can supply panels to others in addition to your business’s installations. This allows you to diversify your business and make extra profits at little cost.

Disadvantages of Portable Rollforming

An investment is required – Easily the biggest drawback of portable rollforming is the fact that an investment of some kind is needed. There are many ways to pay for a rollformer, including paying the entire cost upfront, financing, leasing, or even renting. Either way: You’ll be paying for the machine.

Trained machine operator needed – Training is vitally important when operating a rollformer, and it helps to have a trained machine operator on staff, which means there are additional overhead costs to cover. Additionally, there’s traditionally been a higher turnover rate in this type of machine operator position in the past.

Machine problems stop jobs – If your portable rollformer is having an issue, whether a roller is scratching the paint on the metal or the machine is out of adjustment, it means the job has stopped. When the job stops for maintenance, the installation ceases for a period of time, which could result in a profit loss.

Care and maintenance required – Taking care of and performing regular maintenance WILL make or break a portable rollformer. As a machine owner, it would be your responsibility to properly clean, lubricate, and maintain all of the different parts of your machine. This required maintenance (just like the maintenance of owning or leasing a car) isn’t a disadvantage, but more of a consideration to keep in mind.

Width restrictions – Depending on the profile and the machine type, most portable roofing rollforming machines have a width maximum of around 24 inches. While this is less of a problem with architectural standing seam panels, some exposed fastener systems have been known to have panels with larger widths, which might not be possible with portable rollformers.

Final Thoughts

So what is portable rollforming?

It’s the same concept of in-plant metal rollforming, just on a smaller scale, plus:

- You can take the machine or equipment directly to the job site.

- These machines have tons of different applications and uses, such as agricultural or residential.

- You’re not at the mercy of the panel or gutter supplier and don’t have to worry about wasting time or money on shipping.

- You can even use the machine to diversify your business by supplying cut & drop panels to others.

- Best of all: It produces high-quality metal roofing panels and gutters for your customers.

At New Tech Machinery, we know how important it is for you to be educated on the different types of portable rollforming machines, especially if you’re looking to purchase one. With over 25 years of experience, we are here to answer your questions and help you decide on the best machine solution for you and your needs.