What Are Metal Wall Panels? Pros, Cons, & Types of Metal Wall Panel Systems

Editor’s Note: This article has been updated to include new information since its original publication.

If you’re new to metal construction or researching various types of exterior wall siding, you will find many styles of metal wall panels available. But what exactly are metal wall panels? And what are the advantages and disadvantages of using metal for walls?

Knowing the basics of metal wall panels, the various types you can use on residential and commercial building applications, and the pros and cons of using metal for wall cladding can help you decide if this is the best choice for your metal construction project.

Throughout this article we’ll cover:

- Advantages of using metal wall panels

- Problems that can occur using metal for exterior wall cladding

- Different types of metal wall panels

Advantages of Using Metal Wall Panels

Whether you’re considering rollforming your own metal panels or using a panel supplier, knowing how metal stacks up to other common exterior wall materials like vinyl, brick, stone, or wood is key. Here are some of the benefits of using metal wall panels:

- Visual appeal – Metal wall panels are beautiful in both exterior and interior building applications. They are available in various colors and can be formed into different shapes or popular profiles like flush wall and board and batten.

- Less expensive to install and maintain – Because they are lighter weight, metal panels require less maintenance than other exterior wall systems like brick, vinyl, or stone. Depending on the type of metal wall panel system you choose, metal siding is easier to install.

- More durable – Metal carries a class A fire rating. Metal materials are great protective barriers against fire and extreme weather conditions. When used with a weather-resistant barrier, they can also prevent rain from getting inside a building.

- Sustainable and eco-friendly – Metal wall panel systems are eco-friendly, often recyclable or made of recycled materials, and are used in all sorts of building applications including commercial, industrial, and institutional. Metal siding and roofing can also earn LEED credits.

Disadvantages of Using Metal Wall Panels

While there are many advantages of using metal in a building’s architecture, there are some potential issues you may encounter when using metal as the main component in a structure’s wall panel.

- Oil canning – Oil canning describes a “waviness” that appears in flat areas of a metal panel or metal coil, often caused by stresses on the material itself or during the rollforming or fabrication processes, or due to poor quality or defective coil. It’s typically an inherent characteristic of light-gauge, cold-rolled flat metal products and can happen when using any metal material.

- Corrosion – When different metal types are combined, a negative interaction may occur and cause problems such as water runoff stains and galvanic corrosion. However, with quality paint systems and coatings, metal siding should last decades without corrosion or damage. The type of metal and how it interacts with the climate (coastal, for example) may play a role as well.

- Galvanic corrosion happens when a certain type of metal comes into contact with another type, causing the least noble material to corrode. Water runoff from one type of metal onto a different type of metal can cause staining or corrosion.

- Can experience denting – Although metal wall panels and metal exterior cladding is less damaged by dents or dings, that doesn’t mean that it won’t happen. Especially areas of the wall that are lower to the ground, these metal panels can be exposed to weather, debris, even foreign objects hitting the wall.

Types of Metal Wall Panel Systems

Although there are numerous kinds of metal materials with which you can make metal wall panels, there are three common types of metal wall panel systems used in metal construction. Each one has unique properties, depending on the kind of structure you’re building, environment, installation, and properties.

Single Skin

Single skin metal panels are made of a single layer of metal that’s rollformed or preformed into a specific shape or profiles like a flush wall, WAV, or batten, and are typically made as concealed fastener or exposed fastener panels. Most wall panels of this type can be installed horizontally or vertically and in less time and cost than other metal wall panel systems.

Insulated or uninsulated, single skin metal panels can be made with protective coatings that help fight corrosion and fading. However, they are still susceptible to damage due to their being less rigid, unlike the MCM and IMP panels which have a core between the metal panels. Because of their higher flexibility, they also have a greater chance of oil canning.

Features of single skin metal wall panels include:

- They are lightweight and easier and lower cost to install.

- They are 100% recyclable.

- Single skin wall panels can be installed in almost any environment.

- They are available in various shapes and profiles.

- They are the most popular metal wall panel in commercial building applications.

- They are capable of handling thermal expansion and contraction better than IMPs or MCMs.

Metal Composite Material (MCM)

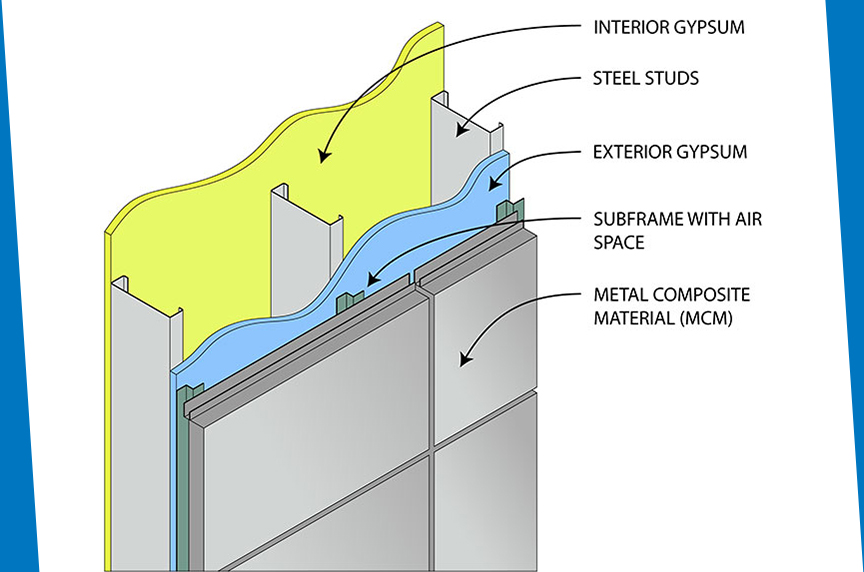

Metal composite material panels are formed by joining two sheets of painted or natural metal sheets (typically aluminum but can also utilize other materials like steel, zinc, copper, stainless steel, or titanium) and bonding them to a polyethylene center.

Why use an MCM panel?

- You won’t have a problem with oil canning in the panels because of the fire-retardent core in between the metal panels.

- MCM panels are typically lighter in weight and can stand up well to harsh weather.

- MCM panels retain their flat shape even when installing them.

- When properly designed, tested, and installed, MCM panels are capable of protecting building exteriors against harsh elements, air, and water infiltration.

Insulated Metal Panel (IMP)

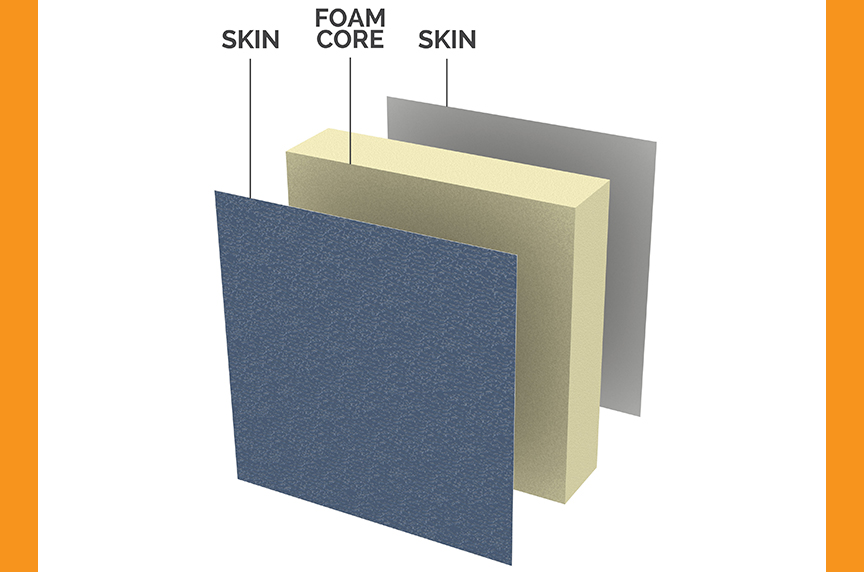

As the name suggests, this lightweight metal wall system is made with two coated metal panels, typically aluminum or steel, formed on either side of an insulating foam center. Because of their insulation capabilities, lightweight design, and quicker installation, insulated metal panels are used in all sorts of building applications.

They make an excellent choice for commercial and institutional buildings, climate-controlled buildings or those used for cold storage, and architectural projects. IMPs can also be installed vertically or horizontally, in various colors, shapes, and panel widths. Because they have the insulation already integrated into the panel, IMPs can be installed in one step and create an effective barrier to air, water, and vapor.

Insulated metal wall panels may be the right choice for certain building applications because:

- They require less maintenance than some other exterior wall cladding or siding.

- They are less expensive to install because of the lightweight nature of the panels, need fewer fasteners, and provide greater wall coverage.

- IMPs are typically factory assembled, not rollformed on-site, and relatively inexpensive to ship to job sites.

What Should I Keep in Mind When it Comes to Wall Panels?

While metal wall panels are growing in popularity in all types of buildings, there is a lot that goes into their design and application. If you’re deciding to use metal for your exterior wall cladding, or want to know which metal wall panel system is right for you, just remember these key points.

- Single skin metal wall panel systems are easy to produce on-site with portable rollforming equipment, but they often require insulation upon installation.

- Metal composite material wall panels aren’t as likely to oil can and are very effective weather and fire barriers upon proper design, testing, and installation.

- Insulated metal panels are very lightweight and great for buildings that need to stay cold or efficiently conditioned.

At New Tech Machinery, we believe that education is the key to happy customers, so we strive to make sure we provide you with the right information and resources to help you determine the best materials, equipment, and profiles to use in your metal construction projects.

Wall Panel Rollforming Machines

NTM has two rollforming machines capable of running metal wall panels.

The SSQ II™ MultiPro Roof and Wall Panel Machine can run flush wall and board and batten panel profiles. It can also run soffit and underdecking for residential or commercial projects. To read more about the SSQ II, click here.

The WAV™ Wall Panel Machine is built to fabricate industrial and commercial wall panels. It runs four different styles. To read more about the WAV, click here.

If you want to learn more about metal wall panels or the wall panel profiles or the roof and wall panel machines available with New Tech Machinery portable rollformers, contact us.